Every machine needs maintenance. Without proper maintenance, you cannot use your tool for a long time. It is true that there are many tools in the market providing a long time service. However, those tools also need proper maintenance.

According to this, an Air Compressor needs maintenance too. It is not too hard to preserve this Compressor. In the market, you will find different types of Air compressors. Do not worry about it. You just need to inspect some basic things. Such as:

Table of contents

The User Manual Of Air Compressor

The user manual is important and very useful for the users. If you read the whole manual then you need not worry about your tool.

In the manual, you will find every information about your Compressor and solutions to some common problems. Therefore, reading the user manual is necessary.

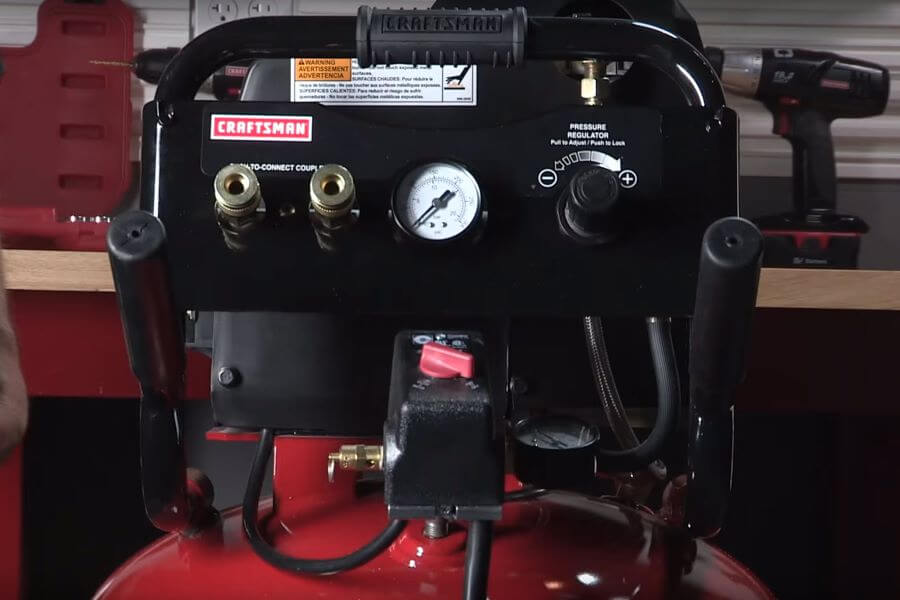

Parts Of The Air Compressor

When it is about the preservation of a machine, you need to be concerned about the parts of it.

In the case of an air Compressor, it is the same. You have to do the following things.

- Observe the screws, nuts, and other tiny things of the Compressor. Make sure that the nuts and screws are tightened enough.

- Clean the intake valves properly. Because you cannot work swiftly with a dirty intake valve.

- Check the hose properly. It is an important part of an air Compressor. If the hose perishes through continuous use then change it immediately.

These are some important things to do during the servicing of your tool.

The Tank

The tank of an Air Compressor is an important part. Because it filters the water from the air and makes the air pure.

During the servicing of your tool, do not forget to clean the tank. Because gradually it fills up with the thick moisture elements and it is not good for your tool. Because this will create many serious issues. For example, the water will spread through other parts of the machine. Moreover, the air will be impure to use.

If your tool is fuel-powered then keep the fuel tank clean. Otherwise, the machine will be worthless.

Oil Of The Air Compressor

For the oil-powered types, oil is the most important thing. You need to inspect the oil and if it needs to change then change it. To do that you need to perform the following things.

- Turn on the Compressor for a few minutes. It will make the machine warmer and thus the viscosity of the oil will become thin.

- Remove the fill cap and the drain plug from the Compressor.

- Then drain the oil into a container and fill your tool with an air Compressor oil of the best quality. Fill the tank with the right amount of oil.

- In the end, replace the fill cap and the plug.

These are the simple methods to change the oil. Do not fill the Compressor with an extra amount of oil.

Air filter

The air filter is another important thing of an air Compressor. It stores the dust and other harmful things in the air so that you can get fresh air.

However, you need to change the filter during servicing. Or else your machine will become useless. To change the filter you need to do the following things.

- Before changing or cleaning the filter, make sure that the machine is turned off.

- Remove the filter top cover from the base.

- Bring out the filter element and clean it or replace it with a new one.

- Then re-install the filter cover.

Thus, you will get a clean and new filter for your tool.

Oil And Air Separator

The oil separator is a very significant part of the machine. It separates oil from the air. As a result, the machine remains lubricated and the air remains dry.

Therefore, you must clean the separator. Otherwise, the machine will not be able to provide you a good service.

These are the important things to observe during the maintenance of an air compressor. You must not miss any of them. Therefore, try your best to follow every rule to maintain your machine.

Conclusion

Servicing a tool is not too hard unless you follow some basic things. Servicing an air compressor is also like that. If you know how to maintain an air compressor then it will be easy for you to use it easily. Moreover, it will serve you for a long time.